Get even better performance from your thruster

Easier maneuvering

Get variable speed control and increased operational runtime

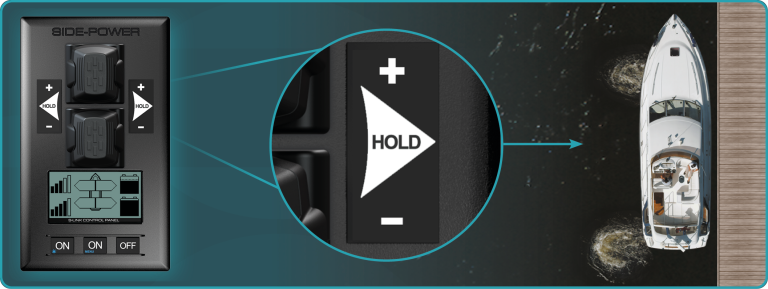

Practical hold function

Keeps the boat safely against the dock while you step off to secure the lines

Reduced noise

Enjoy a more comfortable boating experience with reduced noise

Secure a 30% discount on upgrading to PRO™

We are now running an upgrade campaign with our dealers where you can get up to 30% discount on selected components when you upgrade to PRO™ – the offer includes:

- PPC unit: Controls motor speed for optimal performance

- Control panel: Provides intuitive and easy thruster control

- Upgrade kit: Converts on/off to PRO™ ensuring everything works seamlessly

S-Link™ cables and other accessories are sold separately.

What's involved in upgrading an exisiting thruster system?

To upgrade your bow and/or stern thruster to PRO™, the following steps must be completed:

1. Upgrade the thruster motor

2. Install PPC unit

3. Install S-Link™ cables

4. Connect the new control panel

See the video below for a more detailed description.

Can my thruster be upgraded?

As long as you have a Sleipner (Side-Power) thruster, it is possible to perform an upgrade. This also applies to older models dating back to year 2000.

The upgrade can be performed while the boat is in the water.

Learn more about PRO™ variable speed control

-

Manage the boat alone with the practical hold function

31.5.2024Docking the boat can be challenging, especially if you are alone on board. It requires planning, precision, and often a pair of extra hands. With the hold function, you can rely on your thrusters to keep the boat safely next to the dock, allowing you to moor the boat on your own.

-

Five benefits with PRO™ speed control

15.4.2021Thruster systems with speed control have been around for some time now. In this article, we explore the many benefits of a PRO™ thruster system and why it is an upgrade most boat owners should consider.

-

What is the S-Link™ control system?

2.9.2022S-Link™ is a CAN-based control system used for communication between Sleipner products installed on a vessel. The system uses backbone cables as a common power and communication bus with separate spur cables to each connected unit.