Thrusters

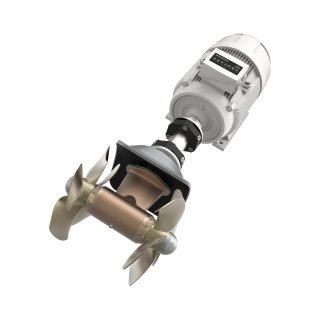

SAC700 tunnel thruster Ø412mm 400V

700kg thrust, horizontal install

-

S-LINK™

S-Link™ is a CAN-based control system used for communication between Sleipner products installed on a vessel.

- Compact and waterproof plugs

- Keyed and color-coded connectors to ensure correct and easy installation

- Different cable lengths, extenders and T-connectors makes the system scalable and flexible to install

-

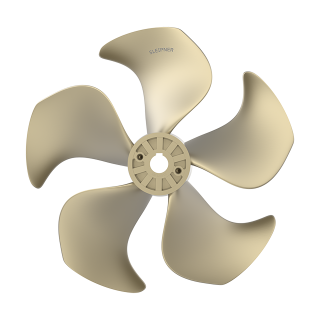

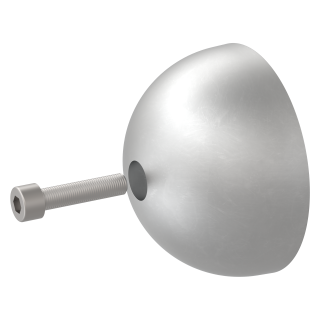

Q-PROP™

The Q-PROP™ has measured noise reductions of up to 75% in controlled environments. The five-bladed skew propeller reduces noise levels while maintaining exceptional efficiency. Some thruster models even see an increase in thrust power.

- The expected noise reduction in average installations: 20-40%

- Upgrade kits are available for most Sleipner thruster models with special adaptors

-

PRO™

A PRO™ thruster system enables you to apply only the necessary power to complete your maneuver. The variable speed control eliminates the noise associated with standard on/off thrusters.

The system also includes a practical hold-function. In a dual system (bow and stern) a single press of a button will keep you alongside the docks - making docking truly a one-person job.

Speed controlled thrusters are the best choice for joystick interaction. -

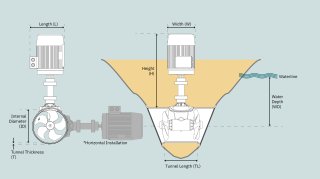

FLEXIBLE INSTALLATION

Sleipner offers installation flexibility to work with the space you have. Our thruster models allow installation at any angle on the tunnel, tailored to fit any space available in your vessel.

-

GRAVITY FEED LUBRICATION

The thruster gearleg is supplied with oil from a separate reservoir above the waterline to monitor oil levels.

-

FLEXIBLE COUPLING

Flexible coupling protects the product’s driveline by compensating for minor misalignments between the shafts of the thruster motor and gearleg.

-

TWIN COUNTER-ROTATING PROPELLERS

Two counter-rotating propellers offer the most thrust at a good performance ratio in a minimal tunnel diameter. This system is used in our larger thrusters for maximum power. Our twin-counter thruster range is the favorite among leading boatbuilders in high-end yachts.

Item code: SAC700/412-C-4-H

SAC700 is a reliable thruster with 700 kg of thrust. It can be mounted as a bow or stern thruster and run continuously without downtime. Suitable for boats between 95-145 feet/ 29-44 meters.

The unit is approved for installation on vessels classified by DNV. Designed for horizontal mounting.

An ideal choice for heavy use, such as in commercial or industrial environments where the boat is often in constant operation.

A remote control is a popular accessory. See some of the important product and safety features below.

Ready to install

AC thrusters are delivered as a complete ready-to-install kit, with all necessary components for easy connection to Sleipner's S‑Link™ control system:

- PDC-301 Drive Controller

- Variable Frequency Drive (VFD)

- Gearleg with propellers and bracket

- Flexible coupling

- AC motor

- EMC Filter

Each thruster is configured specifically for the vessel. No further setup or settings of the VFD (Variable Frequency Drive) are required.

System overview

S-Link™

The innovative S-Link™ control system ensures a quick and trouble-free installation. The system also monitors the operating condition of the thruster and provides continuous feedback to the operator.

S-Link™ also offers the advantage of combining AC thrusters and hydraulic thrusters, all connected to a single common control cable and with the possibility of variable speed control of the thrusters.

The AC thrusters are designed based on many years of volume production of our other thruster series, which has resulted in a series of cost-effective products with high quality. All AC components are supplied by branded manufacturers to ensure quality, high operational reliability, and easy access to spare parts worldwide.

The standard range is designed for 230V or 400V systems but can also be supplied for other specifications on request.

Low Harmonic VFDs

In addition to standard frequency drives, we can supply systems with "Low Harmonic VFD" for installations with specific requirements for THD (Total Harmonic Distortion).

A system with a standard VFD will create a certain level of distortion to the AC network. A system's actual THD (Total Harmonic Distortion) will vary depending on other loads, available generator capacity, total generator capacity, etc.

Sleipner systems with a low harmonic VFD will reduce the harmonic distortion to less than 5%, which will give the following advantages:

- Keep the electrical network clean

- Reduce the risk of disturbance

- Prevent damage to other equipment

- Prevent interference with communications equipment

- Reduced need for oversizing of the generators

PDC-301 Drive Controller

- Communication with VFD by Modbus connection

- Included 3-wire cable for connection to VFD Modbus terminals

- Improved monitoring and diagnostics simplifies commissioning and troubleshooting by real time data logging and readout of historical faults.

- Firmware upgrade through S-Link™

-

A legacy that commits

We’ve lived and worked with the unruly sea for a hundred years. That’s why we develop important features that enables a boat to handle the sea better – that enable you to enjoy your boat, at anchor and at full speed. That is why you wanted a boat, isn’t it?

-

Beautiful engineering

The technology in our solutions is world-class. We know, because we’ve developed it ourselves, just as we manufacture every solution, and follow them until their fixed to a hull, ourselves. This meticulous attention to detail is why your day out always will be better with a Sleipner aboard.

-

Worldwide service

We take pride in our solutions’ function throughout their lifespan. So, we never really let them out of sight, even when they’ve left for distant shores. Our global network is there to ensure continuous optimal function. You know what you get with a Sleipner, today and tomorrow.